Sugar is one of the trickiest commodities to pack at speed without compromising accuracy. Fine granules behave differently from coarse ones. Moisture changes everything. And with volumes running into hundreds of tonnes a day, even a small deviation in weight translates into real financial loss.

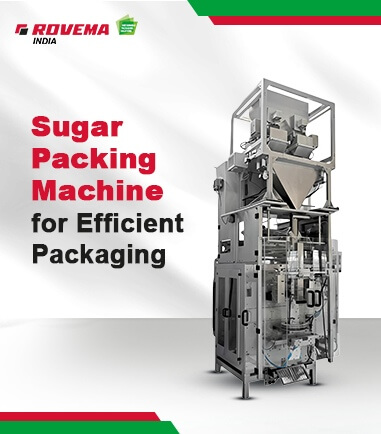

That’s where a Sugar Packing Machine isn’t just another asset on the line; it’s the machine that decides how smoothly your plant runs.

Rovema India has earned that reputation across India’s biggest FMCG, grocery, and staples brands because its systems don’t just automate the process. They make it consistently reliable, shift after shift.

Let’s break down what sets their technology apart.

Why Sugar Needs a Highly Responsive Packaging System?

Sugar is abrasive, slightly hygroscopic, and free-flowing. Most generic filling systems struggle with:

- Dusting, which reduces pack hygiene and affects sealing.

- Granule variability, especially when lines switch between refined, coarse, or fortified variants.

- High speed, but accuracy often drops as speed increases.

- Consistency across long production hours, where machine drift becomes common.

Rovema’s engineering addresses each of these pain points directly instead of forcing a one-size-fits-all setup.

The Engineering Behind Rovema India’s Efficiency:

Here’s the thing: Rovema doesn’t focus on speed alone. Their design philosophy revolves around controlled product flow and precise dosing, two aspects that determine the success of the quality of packing sugar.

1. The Engineering Behind Rovema India’s Efficiency:

A high-speed sugar packing machine usually means dust, spillage, and rework. Rovema counters this with:

- Optimized product infeed

- Anti-dust design features

- Smooth funnel transitions

- Continuous-forming VFFS systems

This is why some of India’s most recognizable sugar brands rely on Rovema lines in their factories.

2. Packaging integrity that holds up during transport -

Sugar gets transported nearly everywhere, including very warm and humid locations. To ensure the integrity of sugar bags, Rovema has developed sealing systems that provide a uniform seal to:

- Eliminate all leakage

- Increase the bags’ burst strength

- Reduce micro tears

Retailers want their bags to be as clean and stable as possible. Rovema’s machines can assist them with this.

3. Flexible formats for every market requirement -

Whether you’re supplying institutional buyers or retail shelves, Rovema supports:

- Pillow packs

- Gusseted packs

- Block-bottom bags

- Larger bulk formats

This range makes Rovema India one of the best sugar packaging machine manufacturers in India for both small and large production facilities.

4. Designed for long production cycles -

Sugar Industrial plants typically allow for a long production cycle, which may last for 16 – 20 hours/day. Rovema machines maintain:

- Temperature consistency at sealing jaws

- Minimal drift in dosing

- Low maintenance downtime

- Stable performance even in dusty environments

This reliability is a major reason why companies standardize their entire sugar line on Rovema over time.

How Rovema Makes High-Volume Growth Easier?

An automatic sugar packing machine should do more than hit the target speed. It should help the plant evolve. Rovema India’s systems support this by offering:

- Lower manpower dependency

- Better line synchronization with upstream and downstream equipment

- Repeatable performance across SKUs

What this really means is: you spend less time firefighting and more time meeting production targets.

Sustainability and Energy Efficiency Built Into the System:

Energy costs are climbing across manufacturing, and sugar production sees a significant load from conveyors, blowers, and packaging lines. Rovema’s VFFS solutions are engineered for:

- Lower sealing jaw power consumption

- Reduced compressed air usage

- High-efficiency drives

- Optimized material usage to reduce film waste

It’s small gains that create real operational benefits over the year.

Why India’s Top Sugar Brands Choose Rovema?

From large refineries to regional brands scaling up, manufacturers consistently choose Rovema for:

- Better pack consistency

- High uptime

- Format flexibility

- Reduced product giveaway

- Long-term reliability

- Speed

- Accuracy

The brand has built its reputation through decades of engineering refinement and field experience, not marketing claims.

Conclusion: When Efficiency Matters, Rovema Sets the Benchmark

Sugar may be a commodity, but packing it right is a precision job. Rovema India has turned that challenge into a strength with machines built around accuracy, clean operation, and long-term reliability. We offer future led customized packaging solutions for your products, know more about us.

If your focus is higher throughput, fewer losses, and packaging that meets modern retail standards, a Rovema Sugar Packing Machine is the benchmark to evaluate against. Contact us now.

FAQs

1. What are the advantages of using Rovema India’s sugar packing machines in the marketplace?

These machines have precision accuracy with an efficient dust-free design, allowing users to package products at high speeds with no impact on seal quality; therefore, they have become a popular choice among many of the world’s largest manufacturers.

2. How can Rovema’s sugar packing machines offer superior efficiency for sugar packaging processes for sugar manufacturers?

The machines permit manufacturers to reduce product giveaways, decrease machine downtime, and increase production outputs during shifts.

3. Can Rovema’s sugar packing machines be used with all types and grades of sugars?

Yes. Fine, coarse, raw, or fortified sugars can all be packaged accurately by using Rovema’s machines.

4. How flexible can Rovema’s sugar packing machines be customized to meet specific production requirements?

Rovema’s sugar packaging systems have been designed with a modular construction; therefore, the systems can be adapted to meet the layouts and production capacities of any sugar manufacturing facility.