Chilli powder isn’t just another spice; it’s the heart of India’s kitchens and a major export product worldwide. However, the quality of the chilli does not depend on the chilli itself, as how it is packed also matters. Moisture, air, and improper filling can quickly diminish both the flavour and colour, sometimes faster than you would expect.

That’s why choosing the right chilli powder packing machine is about preserving freshness, maintaining consistency, and making sure every pouch demonstrates your brand’s commitment to quality.

Packaging Matters More Than You Think:

Spices are delicate. In particular, chilli powder can rapidly absorb moisture and clump, especially if it is not sealed tightly. A good spice packaging machine should do three things at once:

- Keep the product airtight and fresh.

- Ensure every pouch or bag is filled accurately.

- Deliver packaging that looks professional and reliable on the shelf.

Cut corners here, and you’ll pay for it later, both in product returns and lost trust. Know more on Factors to consider before buying pouch packing machine.

What to Check Before You Invest?

1. Manual vs. Automatic -

For very small operations, manual packing may seem practical at first. But manual setups lead to inconsistent fills, sealing defects, and long downtime.

2. Capacity & Performance -

3. Does It Handle Different Pouch Styles?

Some brands prefer pillow pouches to help cut costs, while some brands prefer gusseted and stand pouches because customers see them better.

Having a flexible machine is about being able to switch between pouch styles or different spice powders like turmeric or coriander, giving you flexibility for growth without investing in additional equipment later. Rovema’s modular VFFS machines are already built for this kind of versatility.

4. Accuracy and Sealing -

Chilli powder is lightweight and aerated, making it difficult to dose consistently. Machines with advanced auger fillers compact the powder to eliminate trapped air, achieving uniform weight and density.

Look for consistent sealing pressure and precise heat control — these are key to preventing pinholes or micro-leaks that let in moisture and ruin the aroma.

5. Usability -

The best machines aren’t the most complex; they’re the ones that run smoothly day after day.

6. Price vs. Value -

Of course, the first thing anyone looks at is the price of the chilli powder packaging machine. However, the truth is that a lower cost on the chilli packaging machine than another machine means higher running costs in the long run.

Machines built with precision dosing and long-lasting components deliver better ROI over time. A slightly higher initial investment in a proven supplier pays off in years of reliable performance and fewer maintenance surprises.

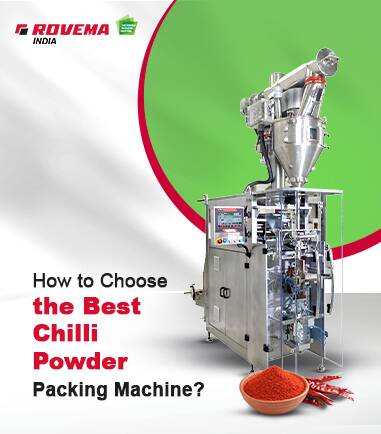

Rovema India: Built for the Spice Industry

At Rovema India, we understand that spice packaging demands both precision and protection. Our automatic chilli powder packing machines are designed to maintain consistent dosing, prevent product loss, and handle multiple spice powders — from chilli and turmeric to coriander and blended spices.

Built with German precision and adapted for Indian market conditions, our systems combine:

- Innovative auger filling that stabilizes powder density and reduces giveaway.

- Flexible configurations for different pouch types and product viscosities.

- Dust-tight sealing zones that keep every pack clean and contamination-free.

- Local service support backed by factory-trained engineers for lifetime after-installation reliability.

The result? Machinery that maintains international standards designed for Indian spices.

Conclusion:

Selecting a chilli powder packing machine is more than a buying decision — it’s about committing to good quality. The right system keeps your product fresh, your operations efficient, and your brand trusted.

With decades of proven vertical packaging expertise, Rovema India offers a complete range of automatic machines for spices, from dosing to bagging, all designed to help your business scale without compromise.

Looking to upgrade your spice packaging line? Talk to our team at Rovema India and discover a system built to grow with your brand.

FAQs

1. What should I consider when buying a chilli powder packing machine?

Accuracy, quality of seals, capacity, after-sales product support, and after-sales service.

2. Are automatic chilli powder packing machines better than manual machines?

Yes, automatic machines will save you time, reduce mistakes, and allow you to grow your operations in accordance with your demand.

3. Is the machine the same for chilli powder and other spice powders?

Certainly. Rovema India’s machines pack a large range of other spice powders, such as turmeric and coriander.

4. How much does a chilli powder packing machine cost in India?

This depends on the capacity and features of the machine. Always think about your long-term return on investment, and not just the price of the machines initially.

5. Why Rovema India for chilli powder packing machines?

We combine the very best of German engineering with local knowledge to provide high-quality, reliable, scalable, and efficient packaging machines.