Packaging decisions rarely fail because of one big mistake. They fail because of small inefficiencies that stack up over time. Extra film here. Manual handling there. Slower packing as SKUs increase. None of it feels urgent until costs start eating into margins.

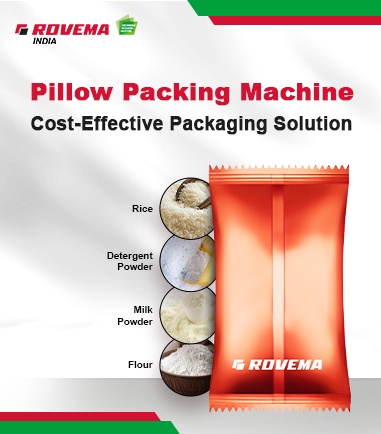

This is why many manufacturers, across food, FMCG, personal care, and industrial goods, eventually arrive at the same conclusion: a pillow packing machine offers one of the most cost-effective ways to package products at scale.

Let’s break down why this format continues to dominate high-volume packaging lines.

Understanding the Pillow Pack Format:

A pillow pack uses a continuous roll of flexible film. The machine forms the film around the product, seals it lengthwise, and then seals and cuts each pack at the ends. The result is a compact, pillow-shaped pack with minimal material and clean seals.

There’s no rigid structure, no unnecessary layers, and no wasted space. That simplicity is exactly what keeps costs under control.

Where the Cost Efficiency Really Comes From?

1. Reduced Labor Costs -

Labor is one of the largest recurring expenses in packaging operations.

A pillow packing machine consolidates multiple steps into one automated process:

- Film forming

- Product wrapping

- Sealing and cutting

Once the line is set up, a single operator can supervise the machine. There is far less dependence on manual packing, hand sealing, or constant intervention.

Over time, this leads to consistent output across shifts. For manufacturers dealing with labor availability or rising wages, this alone makes pillow packing machines a practical choice.

2. Material Savings Without Compromising Quality -

Packaging material costs may look manageable per unit, but at scale, they matter.

Flexible film is used in an efficient manner in pillow packing machines — the film wraps around the product loosely, using only the quantity necessary to protect the product or create a good-looking package.

When compared to a rigid box or using more than necessary to cover a product (overbagging), the cost savings of pillow packing are noticeable. This is one of the strongest drivers of packaging cost reduction with pillow pack systems.

3. High Speed and Reliable Efficiency -

Speed only helps when it is consistent. Pillow packing machines are built for continuous, high-speed operation. They maintain stable performance over long production runs, which is critical for cost control.

This allows manufacturers to:

- Produce more units per shift.

- Lower the cost per pack as volumes increase.

- Avoid bottlenecks at the packaging stage.

High speed combined with predictable output is what turns efficiency into real savings.

4. Versatility Across Products and Formats -

Cost-efficient packaging machines need to adapt as product lines evolve.

A pillow packing machine can handle a wide range of products. By changing the pack size, you can usually have multiple different products; this typically involves making a few adjustments, rather than having to make large mechanical changes to the equipment. Shorter changeovers result in improved machine use and minimized downtime.

Applications of Pillow Pack Machines Across Industries:

Due to their speed and flexibility, pillow pack packaging machines are extensively used in:

- FMCG and packaged foods.

- Confectionery and bakery.

- Pharmaceuticals and medical disposables.

Their broad application range is a clear indicator of their value as cost-efficient packaging machines.

Read our blog on powder packing machine for FMCG brands.

Why Pillow Packing Machines Remain a Smart Investment?

Here’s the reality. Cost-effectiveness never comes from a single feature. This is done through consistent daily savings in small amounts over time.

A pillow packing machine can give:

- reduced labour costs (through automation).

- consistent material savings, via control of film usage.

- higher speeds and stable outputs.

- product and pack size flexibility.

- easy scalability as volumes increase.

This is why this packaging format is used in so many different industries today.

Rovema builds its pillow packing machines for durability and dependable operation, and they help manufacturers take advantage of these benefits on a regular basis, allowing businesses to control their packaging costs and produce consistently in large amounts. We offer future led customized packaging solutions for your products, know more about us.

If you’re looking to cut down on packaging costs but not add complexity, contact us to learn about the most appropriate pillow packing machine for your needs.

FAQs

1. What is a pillow packing machine?

A pillow pack machine wraps products in a continuous film and seals them into a compact, pillow-shaped package.

2. Why are pillow pack machines considered cost-effective?

They lower labor requirements, optimize material usage, operate at high speeds, and deliver consistent output, reducing the cost per pack.

3. Are pillow pack machines a great option for small and medium-scale businesses?

Pillow pack machines are considered a great choice for smaller and mid-sized businesses due to their ability to scale as a business grows, to be highly productive with minimal setup, and to operate very effectively.